Table Of Content

The Pantone Matching System and the RAL Color System are the predominant tools employed for establishing color standards. While the Pantone Matching System is widely favored by designers and engineers in the United States, RAL continues to hold sway in Europe. Manufacturers engaging with global clients are likely to have familiarity with both these systems. Domestika's courses are online classes that provide you with the tools and skills you need to complete a specific project. Every step of the project combines video lessons with complementary instructional material, so you can learn by doing.

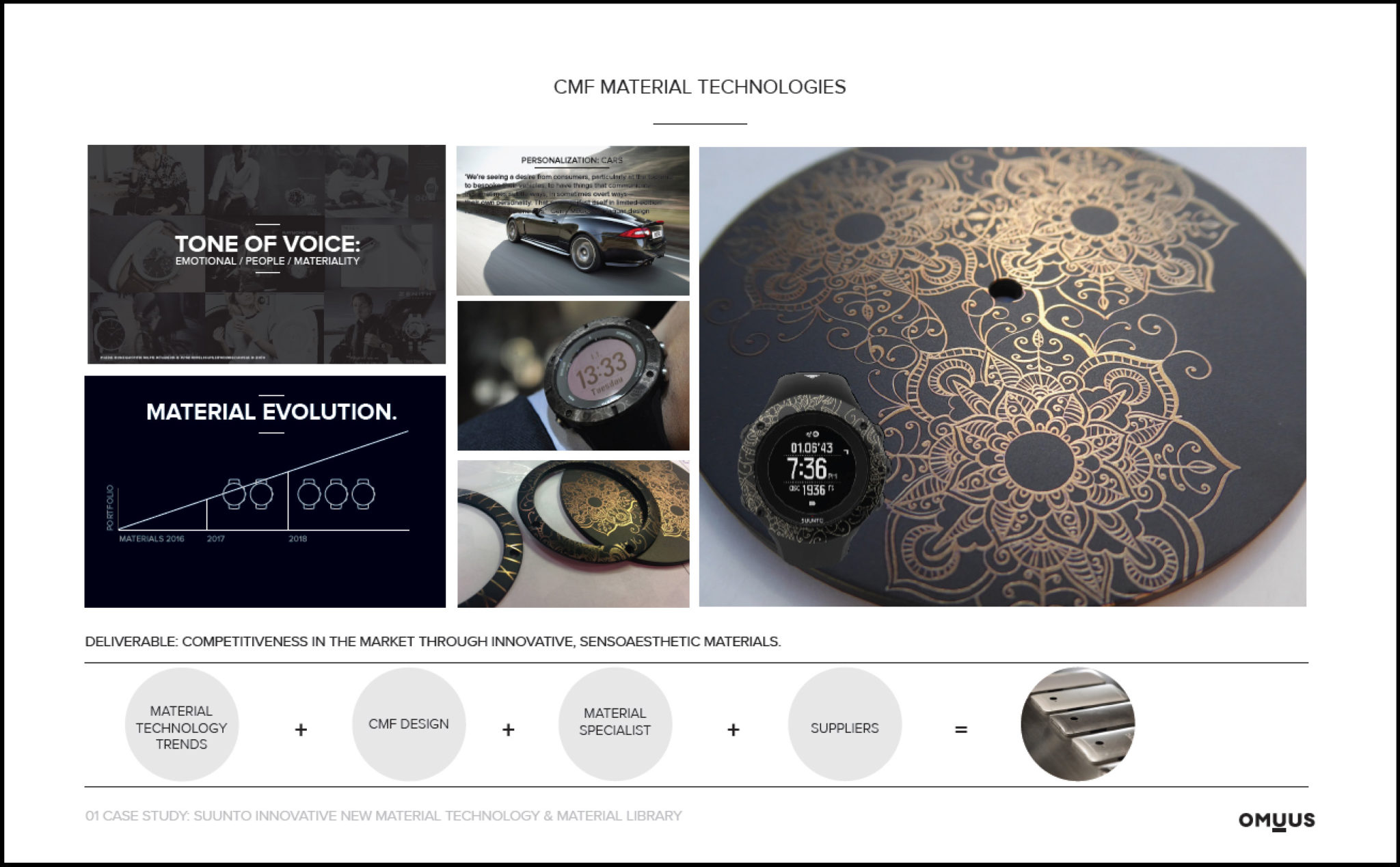

Material Library

Such surfaces are seldom employed for the user-facing side of an injection-molded or plastic part, but may occasionally be designated for the concealed, interior surfaces of parts to reduce tooling expenses. Color is more than just a visual sensation; it’s a powerful tool that taps into the very depths of human psychology. CMF designers meticulously curate color palettes that resonate with a brand’s identity, eliciting desired emotions and creating lasting impressions. The perception of a product as being either inexpensive or high-end, sturdy or delicate, is largely dictated by CMF. The choice of finish and materials significantly affects functional aspects of a product, such as user comfort and ease of maintenance. It’s in the vibrant colors of your favorite sneakers, the smooth finish of your coffee mug, and the soft fabric of your comfy sofa.

The Color in CMF Design

CMF designers deftly select and incorporate materials that not only serve practical purposes but also evoke tactile sensations that captivate the senses. From the silky smoothness of premium leather to the rugged durability of carbon fiber, materials play a pivotal role in crafting unforgettable user experiences. We like to think of CMF as the final stage that distinguishes between prototype and market readiness.

Conducting User Research

CMF stands for Color, Material, and Finish, and it refers to the aesthetic and tactile aspects of a product. It involves carefully selecting the right colors, materials, and finishes to create a cohesive and visually appealing product. CMF design goes beyond just making a product look good; it aims to create a sensory experience that resonates with users on a deeper level.

The Art of Finishes: Adding the Perfect Touch

BMW lands new CMF chief Article - Car Design News

BMW lands new CMF chief Article.

Posted: Mon, 15 Apr 2024 07:00:00 GMT [source]

Sharing as many details about your development as possible will help us to create a thorough briefing and offer for your project. In the appendix of the checklist, you will find further explanations about development phases, international regulations, prototyping, manufacturing and patents. This blender’s color palette focuses the user’s attention on the highly-contrasted power button, highlighting it as a safety feature and as an important first step in operating the product. LEAD provides custom metal parts, plastic parts, and prototype manufacturing services for everyone to quickly prototype, produce, and iterate their products. Essentially, being able to see, touch, and feel is super important, and you can never really replace those aspects digitally.

SLA professional 3D printers can produce fine detail of common molded textures like knurling or minute grain patterns that are lost in other printer technologies like FDM. SPI Standards define how the surface of finished plastic part looks and feels, using a combination of letters and numbers for the naming system. Our new interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of resins. When it comes to direct printing parts with intrinsic color, there are a few options for Formlabs resins. Standard Resins come in transparent (Clear Resin) and opaque varieties (Black, Grey, White), and with Formlabs Color Kit you can mix specific colors of resin. There are a few color systems that have been developed over the years to ensure that nothing is lost in translation between designer and manufacturer.

Designers in general should always be taking in information and references that can be wrapped into designs later.First, get to know your target audience. Gather information about their favorite conscious and subconscious brands, organizations, and objects. Compile all noted aspects of your target persona’s lifestyle into an amalgam. If you like puzzles, this is for you, because people are crazy complex puzzles. Then, from the highest piles, pull tangible information like iconography, colors, graphics, materials, textures, fabrics, etc. Use these to detail your product that fits magically and seamlessly into their life.Without a doubt, seeing it in real-life is the best way to do it.

Explore real-life examples of brands that have successfully leveraged CMF design to build a strong visual identity. We will analyze the strategies and design choices that led to their success, providing valuable insights for your own branding projects. When defining the desired smoothness of a finished part, standards vary by manufacturing process or material. For plastic parts, the most common standards come from SPI specifications for describing the surface treatment of the tooling that is used to manufacture final plastic parts. In many applications, surface finish is important for functionality and durability.

As you can see from the examples in this post, SLA printing is a highly adaptable 3D printing process for any product development team trying to achieve the right CMF characteristics. SPI surface finishes range from untreated “as machined” surfaces to high gloss, with many options in between. For “as machined” surfaces, the witness marks of the cutting tools are obvious. As machined surfaces are rarely used for the end user-facing side of an injection molded or plastic part, but are sometimes specified for the hidden, inside surfaces of parts to save tooling costs. CMF is also often used to refresh or re-purpose your existing product, it's a strategy often used to rejuvenate a product line without the cost of new tooling or manufacturing equipment.

For example, if someone is buying for an industrial context, the consumer will most likely not buy something that easily blends into the environment–they would want something highly visible. In other words, in order to capture a purchase, a product’s CMF needs to appeal directly to the values of your (very carefully defined) target market. If done strategically, the colors, materials, and finishes of your product will outright scream “I belong in your life!

Domestika's courses also allow you to share your own projects with the teacher and with other students, creating a dynamic course community. Laura Perryman is the founder and creative director of Colour of Saying, a design studio dedicated to color and materials in experiential design. She studied textile design at the Royal College of Art in London in 2007, and has worked in the CMF industry since. In 2008, she was a senior designer in the color and material concept department for Nokia for two years. A few years later, she was the CMF lead designer at Arrival, an electric vehicle technology company.

Color is generally incorporated into prototypes through painting or by creating parts with intrinsic color. When producing parts with color built into the part, the primary methods are direct printing or RTV casting of pigmented urethane, silicone, or epoxy materials. However, how CMF makes a difference in a competitive price category will be interesting to see. And will the new device get the same treatment as other Nothing devices in terms of software updates and features? As of now, it is not clear whether the spotted device is a smartphone or any other product. Following the success of its budget-friendly earbuds lineup, Nothing’s sub-brand, CMF, has expanded its portfolio with devices like a smartwatch and GaN charger.

John Deere green, Makita teal, Ferrari red—many brands have made a specific color synonymous with their business. There’s nothing like breathing new life into your home and making it your own. With a vetted list of resources, CMFTO offers a complete array of interior and architectural services to accommodate any size renovation project. This allows us to update any space to meet your current needs, making your home more functional, accessible, and unique to you. Therefore careful consideration, analysis and testing is required to determine the perfect colours, materials and finish of your product.

The active noise cancellation on the CMF Neckband Pro is also higher-rated - 50 dB vs 45 dB. A CMF strategy doesn't only consider how the product looks and feels, it can contribute to the sales, pricing and marketing of your product. When done properly it should help your product stand out from the competition, and can even help to raise the perceived value of the product. We explore more necessary skills for the CMF job, crucial in making it as a successful professional.

No comments:

Post a Comment